Chemical Processing/Cleaning

Chemical Cleaning is the process of removing field service debris and/or hot corrosion products before coat removal of the coated blades.

SAESL employs a fully automated cleaning gantry and manual line that improves flexibility.

SAESL’s capabilities include:

- Waterjet

- Acidic and alkaline cleaning process

- Complex coating removal

- Manual & robotic abrasive blasting

NADCAP (Chemical Processing) accredited

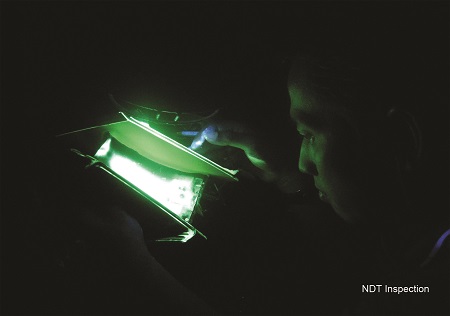

Non-Destructive Testing (NDT)

NDT is a process of investigating and analysing the properties of the components without damaging the integrity of the component.

SAESL provides all-rounded NDT services and expertise and is able to accommodate components with a range of sizes. (i.e Front Bearing Housing to Compressor Blades).

NDT capabilities include:

- Fluorescent Penetrant Inspection

- X-Ray

- Ultrasonic Testing

- Magnetic Particle Inspection

- Eddy Current

NADCAP (NDT) accredited

General Repairs

SAESL provides a wide range of General Repair which include

- Conventional 3- & 5- axis CNC machining, grinding, Vertical Turning Lathe, Milling, Electrical Discharge Machining

- Non-conventional Machining (Laser Drill)

- Fitting & Dressing

- Welding i.e. Manual or semi-automated TIG welding, Laser Welding, interpulse precision welding

- Brazing i.e. wide gap brazing, Single crystal brazing,

- Surface Enhancement processes e.g. glass bead peening and Vibropolishing.

Coating

HPT & IPT blades are coated to protect the aerodynamics of the blades from hot corrosion and oxidation. The coating process is critical for enhancing and prolonging the operational life of the engine.

SAESL possess advanced coating capabilities such as:

- Thermal Barrier coating

- Abradable Coating

- Diff coating

Other stable processes include:

- Isobaric Vapour Aluminising (IVA) – NADCAP(coating) accredited

- Low Pressure/Atmospheric Plasma Spray (LPPS, APS)

- High Velocity Oxygen Fuel (HVOF)

- Twin arc wire application

- Platinum plating

Thermal Processing

Thermal Processing is a refurbishment process of recovering the blade to a “as new’ condition.

SAESL’s extensive thermal processes includes:

- Atmospheric Furnace Processing for coating coating check, post paint curing

- Vacuum Furnace Processing for coating diffusion, braze application, annealing etc.

NADCAP(Heat Treatment) accredited

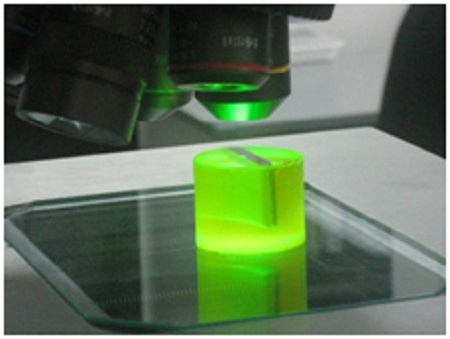

Material Testing Labs

The components undergo testing to ensure the overall integrity and material properties are acceptable.

SAESL provides production and repair development support in:

- Metallography i.e. coating analysis, weldment analysis

- Tensile Testing

- Hardness Testing

Measurement & Inspection

Measurement and inspection are key processes in ensuring that the components are repaired to precision.

SAESL employs a highly efficient inspection management system and competent workforce to perform visual and dimensional inspection.

Examples include:

- Measurement system analysis

- CMM

- Alicona Measurement

- XRF